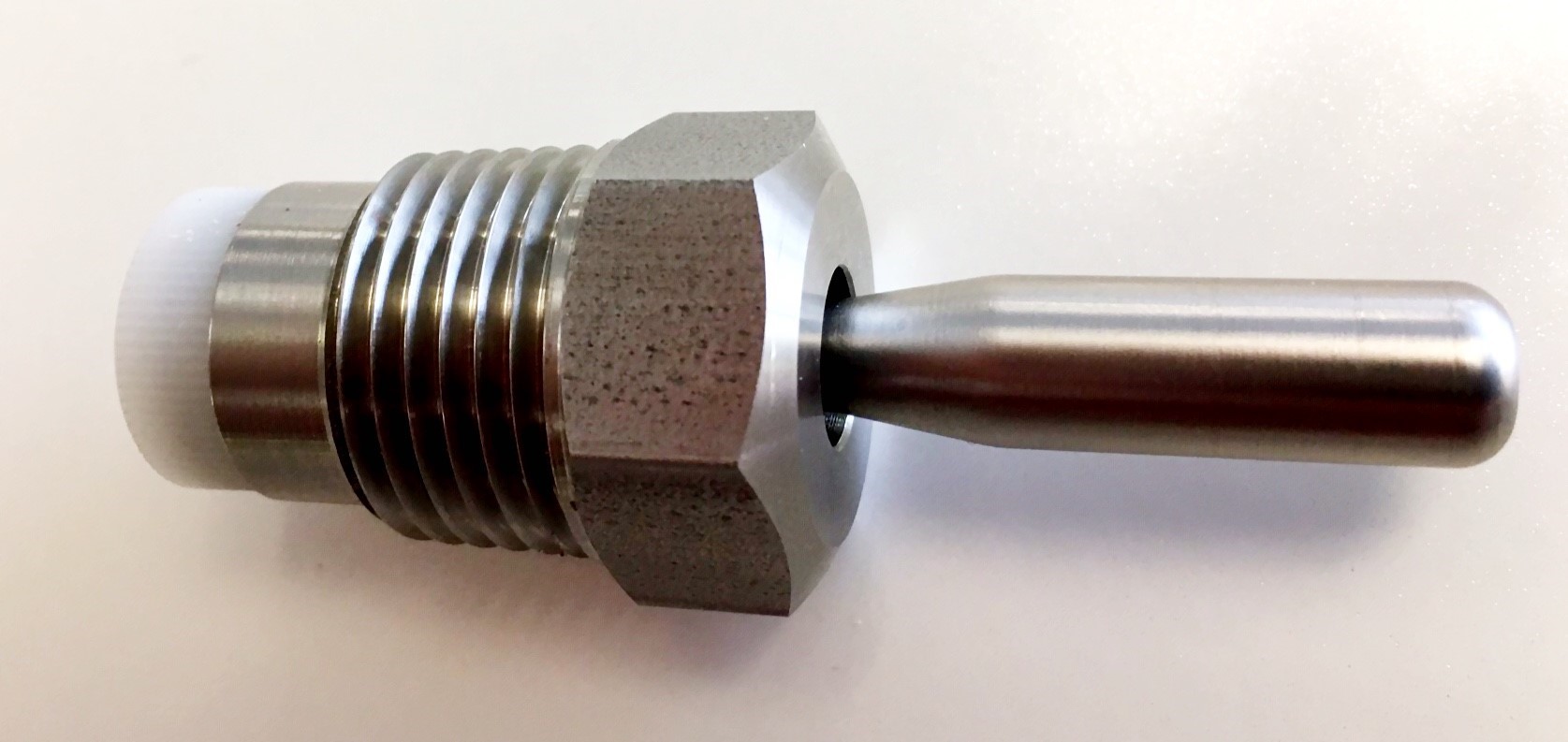

** The design, size and use of every cold water riser /distribution laterals is different for all buildings, hence to size a water / air surge protection valve correctly, the system should be evaluated to determine the maximum flow rate of air entering the system under vacuum conditions. * Versions rated at higher pressures up to PN40 available on request. IMPORTANT NOTE: To ensure proper operation the system must be thoroughly flushed prior to the installation of the WASP valve. An isolating valve should be installed to facilitate maintenance. The WASP valve must be installed at the top of each riser to ensure adequate water-hammer protection. The WASP valve design, ensures effective de-aeration under all pipeline flow and operating conditions, via either one of three discharge orifices. This dampens potential pressure transients when the air valve closes. The WASP valve utilises the large orifice to admit air in the riser thus preventing vacuum occurring when the booster set is down (powered off).ĭuring filling, air is forced through an “Anti-Surge” orifice resulting in the deceleration of the approaching water column due to the resistance of rising air pressure in the valve.

These features are independent of any mechanical devices ensuring reaction in a very low milli second time span. The unique WASP valve incorporates as standard, three design features to automatically protect building risers under all operating conditions, from the destructive surge and water hammer phenomena. Exclusive to Action Pumps, the WASP valve offers air, surge & vacuum protection

0 kommentar(er)

0 kommentar(er)